Luke Smith, director at Adelco, explores the world of fabrics, their composition and which ones are better suited for screen printing.

In today’s world most fabrics can be screen printed, but are some better than others?

To find out, we need to explore the different compositions, properties and construction methods that make up today’s textiles. Textiles can be separated into two categories; natural and synthetic fabrics. Although often a blend of both is used.

History

Looking back at the history, natural textiles such as cotton has been around for millennia. Examples have been found dating back to 5,000 BC, keeping people warm and protected. Different qualities existed depending on the weight of your purse.

The first synthetic fibres were discovered in 1885 by English chemist, Sir Joseph Swan who discovered artificial silk, becoming the ‘father of rayon’. The 18th century was also the beginning of the industrial revolution which opened the way for the mass population to enjoy more comfortable and affordable clothing and home furnishings.

There are so many different types of fabric to think about, Let’s look at the most common ones used today.

Natural fabrics

Natural textiles comprise of a range of plant and animal-based fibres.

Animal: Wool, silk, hide, and hair.

Silk is perhaps the most commonly used animal textile in screen printing. The surface of this fabric is soft which allows for an effective result from screen printing. The best results come from the heaviest of silk, due to the better absorbency of the material.

Plant: including: cotton, bamboo, rayon, viscose, hemp, coconut, linen (flax) abaca.

Plant: including: cotton, bamboo, rayon, viscose, hemp, coconut, linen (flax) abaca.

Cotton is the screen printer’s fabric of choice, due to:

- The high absorbency, the colours really do pop with this textile choice.

- They are soft, extremely durable and permeable.

- Economical and mass produced.

- Cotton can also be obtained organically which for some consumers is an important consideration.

It is also important to note the density of the cotton thread. This is measured by ‘the count’, the higher the number, the finer the yarn, between 1-20 is considered coarse.

Bamboo is becoming much more popular due its softness, moisture absorption, antibacterial qualities and its ability to grow quickly with no chemicals. Making this a sustainable choice, but is it?

There are a few downsides to bamboo, namely the process to manufacture bamboo is much more involved than cotton, the majority of bamboo manufactured for textiles requires a lot more machinery and chemicals than cotton. The fabric is also not as hard wearing. Processes are in place that do not require any chemical treatment for bamboo, but these are not as mass produced.

Hemp is extremely comfortably, and does not need pesticides to grow. Requires a lot less water to grow than bamboo, absorbs copious amounts of carbon dioxide and has a high production turnaround (six weeks to harvest crop).

Viscose is produced from a wood pulp It is like bamboo due to its moisture wicking qualities.

Synthetic fabrics

Today synthetic fabrics have been manufactured and developed to compete with natural fibres, and in some cases such as polyester, are much more desirable to sporting activities due to the elasticity and durability. Other popular types of synthetic fabrics include acrylic, nylon, rayon, viscose, spandex, lycra.

Polyester was first introduced in 1952 and has many qualities, including durability, no shrinkage (like cotton) and is resistant to staining. Dye migration can be a problem but by choosing the right polyester blend, testing your inks and possibly using an under base this issue can be avoided.

Polyester was first introduced in 1952 and has many qualities, including durability, no shrinkage (like cotton) and is resistant to staining. Dye migration can be a problem but by choosing the right polyester blend, testing your inks and possibly using an under base this issue can be avoided.

A blend of the polyester and cotton is a popular option, therefore getting the qualities from both materials.

Construction

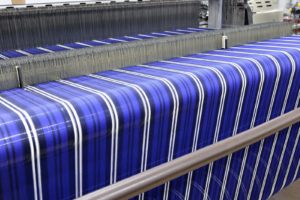

How the fabric is constructed is an important factor to consider when looking at screen printing. Fabrics are either knitted or woven together.

How the fabric is constructed is an important factor to consider when looking at screen printing. Fabrics are either knitted or woven together.

- Knitted – softer, stretch in all directions – nearly all T shirts and sweatshirts are knitted.

- Woven – flatter surface, will only stretch diagonally. Such as denim, tweed and canvas.

As we have mentioned the count of the thread is an important factor. The higher the better.

Different brands offer different qualities, well worth sampling a few to find the best one that works for you.

What is best for screen printing?

Most of the fabrics mentioned can be screen printed on. What you wish to achieve will be the deciding factor on the type of garment your choice. By understanding the options, construction and properties of the different types of textiles available, you can then judge which is right for you.

Saying that, natural fibres do tend to come out on top, and in particular cotton and cotton blends. This is because the construction of the fibre holds up well with the absorbency needed for screen printing increasing the longevity of the print and the garment.

Consumers these days like to have choices and are much more ethically minded, the chances are that screen printers will be printing on more than one type of fabric. It is only by experimenting with different garments (T shirts with the same composition vary vastly from manufacture to manufacture) and by sampling prints and experimenting with different ink types will you achieve the best results.

Printwear & Promotion The Total Promotional Package

Printwear & Promotion The Total Promotional Package