Colours International is very much a traditional screen printer and embroiderer at heart. However, three years ago the team took the decision to invest heavily in its technology to streamline internal processes. Here P&P editor Melanie Attlesey speaks to Ian Bolton, owner of the Dublin-based company, to find out more.

Ian and the team at Colours International live very much by the mantra that ‘what can be digital, should be digital’.

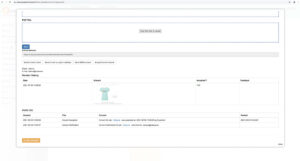

In order to streamline internal processes to enable the production staff to become more autonomous and to create frictionless flow throughout the company, three years ago Colours International began to design its own software in-house.

Taking the way production team worked online was no easy task. Making light of the work involved, Ian jokes that the CASE (copy and steal everything) method was utilised during the development phase. Colours International’s in-house designers looked at software being used by other decorators and took what they thought to be the best bits and improved upon other aspects to create their own in-house software for production staff to use. Gone were the production sheets and instead an online system was launched.

The result was the creation of COMPTS (Colours Online Manufacturing, Planning and Tracking System).

Taking control

Now the small team of printers and embroiderers are able to plan ahead for the week by seeing what jobs are scheduled to take place when and on what machine, meaning they can take control of their own production. With three screen printing carousels and three embroidery machines, Colours International may not be the biggest decorator around, but it certainly is one of the more efficient ones and runs like a well-oiled machine thanks to the software.

For example, the software is able to calculate exactly how long it will take to print a four-colour job, or a two-colour sleeve, a one-colour back and a five-colour front. It takes all the guess work out of the production planning.

“Psychologically they can now feel they can get ahead, because they know if there is a spare moment and there is a job ready for next week, they can bring it forward themselves. They don’t need to double-check with anyone,” explains Ian.

Printer Tanya McDerrmot, who uses the software, provides her thoughts: “The system makes everything a lot easier. I can see at glance what is ready to go. I don’t need to check with other people on stock screens, I have all the information in front of me!”

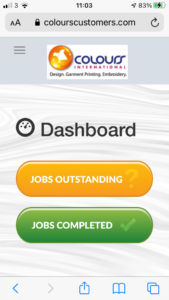

The plan was to always extend the software for customers’ use, to allow customers to be kept in the loop at every step of the ordering process. The onset of the COVID-19 pandemic in March 2020 accelerated Colours International’s plans to do this.

Ian says: “We have transferred our complete production system online with automated access granted to each customer. At present the customer can check virtually all the most pertinent items relative to their order.”

The software has also been developed to handle the logistics of global events. Any event which takes place across five continents on one day, could create the potential for a logistical nightmare when it comes to printing thousands of T shirt which need to be printed and shipped to individual addresses across the globe. But not for Colours International thanks to its software.

Ian explains: “If you register for an event and you want one T shirt, five T shirts or 10 T shirts, the event’s registration site is linked to our logistics portal which will work out the most efficient way to send you the T shirt. For example, if you are in the UK, the system will also automatically produce a customs label too. We don’t just supply the T shirts, we print them, pack them and dispatch them.”

Registrants for an event are able to log on and track the progress of their order. The same applies to the organisers of the particular event, who are able to log on and see just how many orders have been received and how many T shirts Colours International has printed.

The software can also handle just in time stock handling for uniforms and can be directly linked with Shopify websites for direct shipping.

Advance in technology

As with every advance in technology, there are always people who prefer things the way they were. On the whole the online ordering process has cut down on the number of unnecessary calls and emails received from customers chasing for updates on stock delivery and such like, but there are a small handful of customers who still prefer to call, mainly just for a chat.

“It really has changed the dynamic with our customers. It hasn’t stopped the personal connection we have with them,” says Ian.

The next step for Colours International and the development of this software is to make it more user-friendly for customers on their mobile phones. At the moment the mobile optimisation is not the best. Another thing that the team is working on is the introduction of a live webcam feed, so customers can log on and physically see their items being printed or embroidered.

Ian concludes: “Over the past number of years, our technology suite as become an integral part of our business.”

Perhaps software like the one developed by Colours International is something that all garment decorators should consider if they want to streamline their internal production process and online ordering system for customers. Ian firmly believes this is where the future of garment decoration lies.

Printwear & Promotion The Total Promotional Package

Printwear & Promotion The Total Promotional Package