Outsourcing is on the rise again – but what about quality?

Now, more than ever, businesses are looking to streamline their costs and outsourcing remains a key strategy. Embroidery companies are either outsourcing some or all of their digitising needs in order to save time, money or both. However, the quality is not always up to their high standards.

An embroidery business is judged on quality alone, not the speed of delivery or the costs. If you can master the trifecta then your business is onto a winner.

How do you maintain quality?

This is one of the main questions we hear when speaking with our customers on this subject and our response is always the same.

‘Do not completely rely on your outsourcing partners. You have incredible experience and expertise so don’t forget to use it.’

You have an experienced machinist who knows your specific embroidery machines best. Use them to sample the digitised designs on the correct fabric and harness their experience.

Designs may need a few simple tweaks such as fixing the lettering, adding/ removing underlay, correcting alignment issues or simply reducing the stitch count for more efficient production.

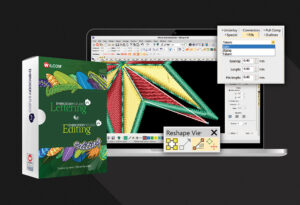

Take control of your quality assurance and choose to do these tweaks in-house. Without the need for a full Wilcom digitising solution, you can simply use EmbroideryStudio e4.5 Editing. The software is purpose-designed to allow your in-house team to make these amendments and includes a complete library of 226 professionally digitised embroidery fonts.

This will not only save you additional time going back-and-forth with your outsourcer, but enables your team to make a change and immediately test it out on your production embroidery machine.

The team would also recommend adding Wilcom’s EmbroideryConnect WiFi Device to create a cost-effective wireless embroidery machine network solution. The benefit aside from the need to constantly travel with designs between your PC and embroidery machine, is that you can ensure the correct updated embroidery design is loaded to the machine, avoiding re-running an old stitch design during testing or worse, during your final production.

Speak to your local Wilcom stockist for special bundle offers.

So do not hesitate. Take back control of your embroidery quality and the future of your business.

Printwear & Promotion The Total Promotional Package

Printwear & Promotion The Total Promotional Package