M&R makes a variety of equipment that simplifies the production of high-quality transfer prints. Described below are just four of those products.

Saturn Platinum II Flatbed Graphic Press

Saturn Platinum II Flatbed Graphic Press

M&R’s Saturn Platinum II is ideal for transfer printing. Compact and affordable, it sets the standard for high tolerance printing in a small-format flatbed graphics screen printing press, with a level of control and quality normally found only in large, expensive presses. That degree of precision enables Saturn Platinum II to produce exceptional results on heat-transfer substrates. The user-friendly control panel simplifies operation by using icons to identify press functions. The press also features M&R’s SoftVac whisper-quiet, high-volume vacuum system, with independent and adjustable vacuum and blowback. The digital keypad with alphanumeric display simplifies programming, and micro-registration with visual guides makes setup and adjustment fast and simple.

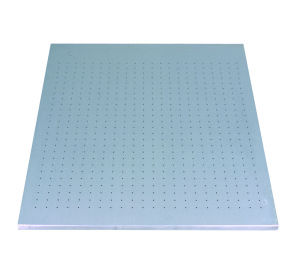

M&R’s SureVac Vacuum Pallets turn most screen printing presses into precise, affordable transfer presses. M&R offers single-station and multi-station SureVac Vacuum Pallet Systems for manual and automatic presses. With a single-pallet system, the operator can change to textile printing without first replacing the vacuum pallet with a standard pallet. SureVac enables textile printers to enter the world of high-quality transfer printing for far less than the cost of purchasing a flatbed or multicolor graphic press. No additional space is required, and the presses can alternate between transfer printing and traditional textile printing.

M&R’s Mini Sprint, with its 97cm (38in) belt width, is the perfect way to dry transfer substrates. Not only does it have the highest production capacity in its class, it’s also the most energy efficient. Heavy-duty thermal insulation prevents heat from migrating from the conveyor dryer chamber into the workplace, while CoolSkin technology leaves the dryer skin cool to the touch. Fast cure rates and high product throughput maximize dryer capacity and minimize per-unit cost.

Sentry Flatbed Press Takeoff System

Sentry Flatbed Press Takeoff System

M&R’s Sentry gripper-style takeoff is ideal for removing transfer substrates from Saturn Platinum II.

Most takeoff functions are accessed at the control panel of the press. Captured bearings eliminate rocking and assure smooth movement. The grippers feature tool-free adjustment and can be used in any combination. They can be positioned from side-to-side and moved forward and back on the takeoff housing, and the air regulator allows operators to establish the precise gripper pressure for each substrate.

For more information call 01562 829 009, visit www.daveroper.co.uk or www.mrprint.com

Printwear & Promotion The Total Promotional Package

Printwear & Promotion The Total Promotional Package