This month Resolute DTG’s managing director, Colin Marsh, reports on the new range of RTP garments that do not need pre-treating before direct to garment printing.

Not having to pre-treat shirts – what does it really mean? Since the inception of direct to garment printing the process has required a pre-treatment solution to be applied before printing to stop the white ink soaking through the garment. This is the same for all DTG printers no matter what brand or price tag unless you are hybrid printing.

Normally applied with anything from a brush, roller, spray gun, dedicated pre-treatment machine or in-line, the process is compulsory. In the past many companies have tried to master the art of treating the shirt before it is purchased, this would save the printer time, money and the space needed to apply the pre-treatment which is a big plus. Buying a shirt ready to print will of course cost a little more than performing the process yourself, but unlike traditional spraying an RTP shirt can be printed anywhere including over the seams, on the sleeves and printed front, back or both.

Who can use these RTP shirts?

I have personally witnessed a lot of testing on different DTG systems while working in the US this year.

All the DTG systems tested performed exceptionally well no matter what ink was being used. This does go against the manufacturer’s recommendation but it is of course testament to the RTP garments as they printed and washed very well in every case.

As a general rule a little less white ink was required to obtain a good print in all the tests making prints on these shirts a little more economical than conventional pre-treatment.

How much will they cost?

The $64 million dollar question! At what price will this convenience come? Taking into account the cost to pre-treat a garment, front and back including the left and right sleeve the shirts will be priced competitively in comparison.

What you are guaranteed to save is a lot of time with the added benefit of worry free consistency and great durability in the wash.

What is the fabric quality?

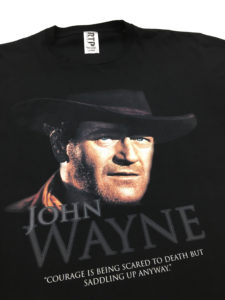

Manufactured in ring spun cotton with a 160gsm weight the RTP garments have a fashion cut with a modern neck line. Keeping fibres to a minimum has been a key point in the quality of print and matt finish you achieve when using these shirts.

Who will sell the RTP garments?

Unfortunately, this information has not been made public yet and is currently unavailable. I would estimate an announcement will be made once the official launch date comes in 2017. One thing I can say is, where possible they will be available globally and this will require a multiple supply chain to be put in place.

Want to try the RTP garments?

Current availability is restricted to authorised beta testing companies and demonstrations at exhibitions.

During the beta testing these shirts are only manufactured in black and white, a colour range is planned at a later date when the official launch is announced.

During the beta testing these shirts are only manufactured in black and white, a colour range is planned at a later date when the official launch is announced.

In early 2017 a limited amount of RTP garments will be made available for open testing in the UK. If you are interested in trying these amazing garments watch out for online announcements on industry related websites. To date, sample garments are scheduled to be supplied via a web portal, once this information is made available certain details will be required in order to obtain your sample. This will be simple and limited to the machine make and model, the ink brand used and where to send the sample.

Next month, I will be revealing a complete walk through of how to successfully print dark polyester on a wide range of DTG systems. The much sought after process will be covered in detail and the results are pretty amazing.

Printwear & Promotion The Total Promotional Package

Printwear & Promotion The Total Promotional Package