Approximately 50% of Balmoral’s business comprises of bespoke manufacturing from its factory in Ayrshire and its overseas partners. MIKE CARDEN answers a couple of questions on the bespoke manufacturing process.

Q. Describe what bespoke manufacturing means for Balmoral Knitwear?

A. A huge part of Balmoral Knitwear’s business is the bespoke manufacturing of pullovers, cardigans, scarves and hats. These might be in special shades or particular designs or both, made in Balmoral’s own factory in Ayrshire. And of course we also have off-shore partners who we can use either where the quantities are reasonably large, or where our partners have particular skills and machinery that we do not. There is probably no other knitwear manufacturer in Britain that makes the range of bespoke knitwear we do for corporatewear, school uniform, promotions, cricket and so on.

Q. How does the bespoke ordering process work?

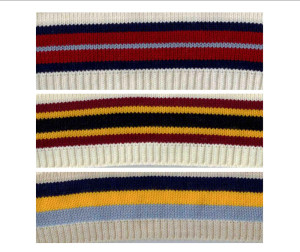

A. The process of making bespoke knitwear varies with what is required. At its simplest, often for schoolwear, a bespoke style will simply be a standard pattern of pullover or cardigan knitted in a particular school’s own shade, perhaps with striped trim in the neckband, cuffs or welt. We stock a pretty wide range of yarn shades in the factory, so very often we can make bespoke styles from that yarn stock. In that case, the minimum is just 24 garments, and the lead-time is four to six weeks.

The next level of complexity comes when a new shade is required. Most of our yarn spinners will supply batches of different shades of yarn for orders of about 100+ garments – though it does vary. In our 50% wool 50% acrylic yarn, the spinner has a library of over 3,000 shades. They keep a single cone of each, enough to make a sample or two, and Balmoral has exclusive access to that library in the UK because of the large volume of yarn we buy from them. For other yarns, we would probably need to dye to match – either a Pantone shade or preferably a piece of fabric from a matching garment.

A third level of complexity comes with bespoke styles of garment. We have programmable Japanese Shima Seiki knitting machines which allow us to create fashioned knitwear alongside the cut-and-sew knitwear more traditional to schoolwear and corporatewear. We have also invested in Shima’s Apex technology allowing us to create designs on a computer program by selecting single stitches or blocks of stitches. We can work from sketches or from garments bought in shops – the more information we have the better. We can then agree a style, quote an estimated price, and make a sample. We do charge for that: there are significant costs in making samples. Once the sample is approved we can go to manufacturing – usually with a four to six week lead-time if we are making in our factory in Scotland and a little longer if we are using one of our off-shore manufacturers.

Q. How bespoke can somebody get with their choice of garment?

A. Colour and style are commonly changed, and so long as the quantities are suitable, there isn’t much that we cannot do either from our own factory in Scotland, or from one of our off-shore partners. There are, however, bespoke styles where we will turn an enquiry away because we do not have the necessary skills or expertise to do a good job.

Material tends to be a different matter. We generally need to work with yarns that we are familiar with, and that we know will run on our machines. Not all yarns are suitable, and not all spinners are as reliable as we require. So we do generally prefer to work within our standard range of yarns: TPA 100% acrylic; 50% wool 50% acrylic; 50% cotton 50% acrylic; Pure New Merino wool; British wool; and various wool-nylon blends.

Q. What percentage of your business does bespoke manufacturing comprise? Do you expect this to grow over the next five to 10 years?

A. Bespoke manufacturing is about half of our business, and that is growing. We are increasingly flexible as regards bespoke styles; for example we have a design program which can scan images and create knitting programs. So the range of types of customers we can supply is increasing.

Q. In which ranges do you currently offer a bespoke service?

A. It’s not the case that we only offer our bespoke service to schoolwear and corporatewear markets. One example is that we are increasingly making bespoke styles for the promotional industry, where we can create jacquard patterns to knit into the fabric of a sweater. Christmas is a good time for this of course: bespoke Christmas sweaters for Britain’s businesses!

And of course a significant part of our business is making cricket sweaters to order with bespoke stripe colours, whether for clubs or schools; we will make a minimum of just six. We also make knitwear in team colours for the lawn bowls market. In fact, we have a system where we make a range of shades of bowls knitwear about eight times per year, allowing customers to order with no minimum quantity at all. So we certainly do offer bespoke manufacturing for sportswear, wherever it is appropriate.

Another new development is that we are now making country knitwear using British wool. These are heavyweight sweaters, with or without patches of mock suede Alcantara. Our customers for these tend to be in the hunting and shooting side of sports/countrywear, or smaller British retail brands targeting the more well-off customer, who will pay for quality and for a Made In Britain tag.

Q. You offer bespoke manufacturing from your factory in Scotland and from your partners overseas. Do customers generally prefer garments made in Britain? If so, what is the appeal?

A. There seems to be a sea change in how the British public and British industry feel about products made in Britain. Just a few years ago, I would have said that ‘Made in Britain’ was not seen as relevant to our customers. Today it is. Even some of our bigger corporate clothing customers are specifying that certain orders must be made in our own factory rather than at one of our off-shore partners; the ‘Made In Britain’ tag has finally been recognised as being significant for the whole country – keeping skills here, helping the balance of payments of the country, taxes paid here, and jobs kept here.

Q. You’ve exhibited twice at the Meet the Manufacturer show in London, which champions British manufacturing. Is this an area which is making a comeback and an aspect which customers now look for when ordering garments?

A. The Meet the Manufacturer show targets the retail market – from small-scale designers to larger brands. It is not an area we have traditionally worked with, but the prospects we meet there have been specifically interested in our British wool range of knitwear. The show has also given us enquiries from overseas: we are currently into our second season with a significant Japanese customer who we originally met at the first Meet the Manufacturer show last year.

Q. Why do customers find bespoke manufacturing appealing?

For the decorated clothing industries, the appeal of bespoke manufacturing is to be able to offer styles and designs that their competitors cannot easily replicate. And for their customers, the appeal is to have uniform or promotional garments which look different to their own competitors – not just a navy sweatshirt with an embroidery; but a pink sweater; or a green one with stripes; or scarves with stripes in the corporate colours; or ski hats with a club logo; or Christmas sweaters with the company logo knitted across the chest. The possibilities are endless!

Q. Do you have any advice for readers looking to source bespoke garments?

Yes. Go for it. It’s easier than you might suppose!

Printwear & Promotion The Total Promotional Package

Printwear & Promotion The Total Promotional Package