The Tajima TMEZ is the world’s first Tajima embroidery machine with Intelligent Thread Management.

From the very start running and getting the best results from commercial industrial embroidery has been a dark art, whether it’s framing up and getting a consistent position on the garments, or using the correct weight backing paper or just simply knowing how and when to adjust tensions to stop fabric puckering or the bobbin thread appearing on the top surface of the finished embroidery, and not to mention satin borders that never seam to fit or change randomly? And yes it happens to everybody not just you!

The thread tensioning systems on most machines has not really changed since the introduction way back, in essence a series of metal discs pushed together via a light gauge spring controls the amount of tension that is introduced into the lockstitch sewing system. A good operator can in a word get a feel for what tension is used on what design and fabric. This is a skill that takes years to learn and to many a new operator seems daunting as the slightest wrong turn can change the whole look of the embroidery and the thread trimming resulting in long uncut threads end snapping/ fraying and in some cases even needle breakage!

A perfect world would be a set of thread tension parameters set out from the outset, based on the best results for a given design/ stitch type/ base fabric, Tajima ITM has solved this with an electronic control of the thread used in the stitching system ITM.

The new Tajima TMEZ has the ITM option, this gives the ability to replicate the same result on different machines and head combinations as the tension file can be downloaded and added to other machines, in the foreseeable future the manufacturers will give the customisation factories the exact file combination with the exact tension settings making the whole set of different designs and fabrics a thing of the past, even the lightest stretchy fabrics will get the crisp clean results we all strive to achieve.

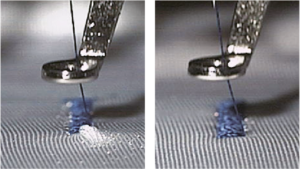

As you can see from the pictures the fabric lines and grain on the left-hand side have pulled and the satin stitch has formed its own tunnel. As the design progresses and stitch angles move the design will appear puckered around the edges and in some cases the fill stitch will move away from the satin border leaving a void.

The picture on the right shows the ITM system deployed, very little fabric movement is visible and the tunnel affect is virtually undetectable.

Another movement forward with the Tajima TMEZ series of machines is the Digital Controlled Presser Foot. The height/ pressure of the machine’s presser foot is set as a parameter in the easy to use Windows control system and then saved away. This setting helps with thicker fabrics like leather, quilted coats as well as the ultra-thin voile/ satin fabrics used in wedding gowns.

Printwear & Promotion The Total Promotional Package

Printwear & Promotion The Total Promotional Package