In the third part of Madeira’s series of articles looking at how making the right embroidery decision can protect against the harshest of elements, this month the team put safety first and combat fire.

In the third part of Madeira’s series of articles looking at how making the right embroidery decision can protect against the harshest of elements, this month the team put safety first and combat fire.

Firefighters need protective clothing but they are not the only people at risk of coming into contact with flames in the workplace. Workers in many other industries such as gas and oil are in an environment where there is a risk of garment ignition.

If fire is a potential hazard then there is a fundamental duty for employers to ensure their workforce is adequately protected by providing heat and flame resistant clothing.

When describing the protective properties of fabric and thread the terms fire resistant and flame retardant are often used, however, it’s important to know the difference, each offers a different level of protection.

- Resistant – describes a material inherently resistant to catching fire when exposed to a flame, it does not melt or drip and will self-extinguish therefore prohibiting the spread of fire.

- Retardant – refers to a material that has been chemically treated to self-extinguish.

Untreated fabrics and embroidery threads are combustible, meaning they will continue to burn even after the flame has been removed. Fire, as we all know can spread extremely quickly at considerable risk to the wearer. Protective clothing is essential across a range of industries from motorsport to electrical and chemical, not forgetting firefighters and military personnel, and could save the wearer from serious injury or death.

When such clothing requires an embroidered badge or corporate logo it is important that the embroidery thread provides the same level of fire protection as the garment itself. For such applications flame resistant threads are now widely available and must be used.

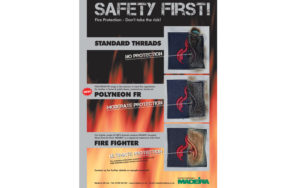

When your embroidery must meet fire regulations there are threads out in the market which fulfil different levels of safety requirements.

For optimum protection, the most fire resistant embroidery thread currently on the market is Madeira’s FireFighter thread made from 100% Aramid, the fibre used for Nomex. This flame resistant thread is designed not only to resist ignition and prevent flames from spreading but also to self-extinguish once the source of the fire is removed.

FireFighter conforms fully to standard EN ISO 11612 and tested accordingly, as shown in the image. Beware home testing because if you take a single strand of FireFighter thread from the cone and ignite it, then the lubrication coating will burn off or carbonise very quickly. However, when in the form of surface embroidery, due to the Aramid content it will not ignite, melt or drip providing ultimate protection for the wearer.

Polyneon FR is the next level, developed to meet fire regulations for textiles in home and public décor, hotels etc. offering the protection suitable for these environments. Unlike many threads in the market purporting to be flame retardant, PolyneonFR has a special compound added during the spinning process which not only reduces the thread’s flammability and slows the spread of fire but also ensures the flame retardant protective finish will not disappear through wear or washing.

To achieve optimum protection and ensure all safety standards are met, it is essential to also use suitably fire retardant backing and underthread.

Printwear & Promotion The Total Promotional Package

Printwear & Promotion The Total Promotional Package