It may be phrase not commonly used, but in terms of personalising promotional products and garments it should soon become the norm. Companies have been targeting the B2C market in the form of unique personalised products for many years now and it’s time you got in on the act too. P&P editor, MELANIE ATTLESEY, reports.

Mass customisation by definition is a manufacturing technique that combines the flexibility and personalisation of promotional products and garments with the low cost units associated with mass production.

In order to bring this concept to the forefront of the personalisation industry, Gateway 3D hosted its inaugural Create, Sell, Print event on July 14. The event brought together those in the industry already benefiting from mass customisation and those looking to move into the sector. During the event Gateway 3D’s managing director, Andrew Talbot, took to the stage explain in depth about the concept.

The concept explained

Firstly Andrew explained that there are several factors driving the mass customisation market forward. These include printing technology, e-commerce, cultural factors and fashion. These factors combined are enabling consumers to buy products unique to and custom-made for them easier than ever before.

There are many market sectors where mass customisation can apply. Big companies such as Moonpig have been using the concept of mass customisation for many years now, enabling customers to create customised greetings cards online and have them posted out to the recipient direct. Both Nike and Adidas have created websites where customers can build and design their own trainers, shoes and bags. These brands have even built factories in Europe just to create custom footwear.

But forget greetings cards and footwear – what market sectors can you apply the concept of mass customisation to? Think, home décor, trophies and awards. Home décor, according to Andrew, is probably the fastest growing market sector for mass customisation. Home owners seem to love the idea of personalising their furniture, cushions, lamp shades and curtains. Producing customised furniture may seem way out there, but consider offering smaller personalised items such as cushions. There are printers out there which allow you print these items using dye sublimation. In terms of trophies and awards, although this is a niche market, just remember nearly every town had its own trophy shop which would engrave products at one point. Now this market sector is moving online as consumers find more and more interesting products they wish to have engraved and personalised.

According to Andrew there are many market sectors not yet touched by mass customisation. If you can find a niche market to mass customise you could be on to a winning idea. For example one company in the UK turns over £1m a year selling personalised tea towels to schools.

Andrew explained that Gateway 3D’s aim to is enable the personalisation of any product and it does this through its Custom Product Platform. Suppliers can upload their products to this platform to configure online personalisation. Options for personalisation include customisable text, image upload and colour or texture changes. Whatever the product CPP enables customisation to take place online. Once this platform is in place, products can be easily added to a website, mobile app, instore kiosk or social media page. After the customer has placed their order online, Gateway 3D’s order management system takes over and delivers production ready artwork to a printer or embroidery machine. The system will also notify the customer when their product is on the way.

Using the concept of mass customisation and its software, Gateway 3D is on a mission to eliminate minimum order quantities. According to Andrew around 90% of the businesses in the UK are micro-businesses, which means they are not going to order hundreds of the same product. This also means that if you are in the promotional products trade you can only realistically target 10% of the market, unless you head down the route of mass customisation. By eliminating minimum orders you can expand your market base, but you can also turn the product you are selling into a B2C product. For example instead of your local hairdressers having to buy a bulk order of mugs, they will buy five. For those in the promotional products industry, mugs can now be personalised and sold on mass in single orders.

Mass customisation in action

Wilcom has worked in partnership with Gateway 3D to create an Embroidery Web API. This is Wilcom’s third generation embroidery automation software tool kit.

This API enables garment decorators to add embroidery capabilities to their websites. Garment decorators can use the API on their websites to go from order to production stitch date automatically. Wilcom has found that the most common use for the API is for embroidery companies to enable their customers to personalise embroidered garments with their own embroidered text and/or image.

Customers ordering personalised embroidered products through the API are able to see realistic preview images of their orders. The API creates production ready embroidery stitch data for existing designs, personalising .EMB lettering template designs, and newly created original lettering and monogram embroidery.

The API does not provide the user interface. Garment decorators are required to have their own website already in place. A web developer will be required to create a customised web application to provide the user interface to the customer.

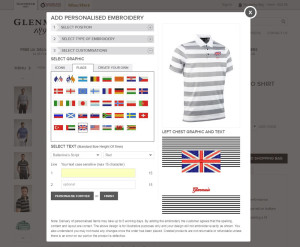

Glenmuir, a Scottish golfwear brand, is one of the first companies in the UK to put this API into action and enable the concept of mass customisation for customers. The API has been functional on Glenmuir’s website for the past year.

As managing director, Mikhel Rui, explains: “Glenmuir are leaders in the embroidery and personalisation of products, but we did not have the service available to our online e-commerce customers. The API achieved this in a functional and visually presentable manner.”

The API allows an end user to add a logo, monogram, or a logo with a monogram on various positions such as left chest, right chest, or any of the sleeves and back neck on the majority of Glenmuir’s shirts, knitwear and outerwear jackets. Once a customer places an order, Glenmuir’s machinists embroider the personalisation. The products are usually dispatched within 48 hours.

As approximately 60% of Glenmuir’s business comprises embroidered products, across its B2B and B2C e-commerce business, it is easy to see why Glenmuir wanted to build the API into its website. Mikhel adds: “In this day and age of digital e-commerce customers and increasing consumer expectations and demand for personalised service, we think it is something which our customers demanded so we created this personalisation module for them.

“Gone are the days where our trade and e-commerce customers order products in 12, 24 or 36 pieces. These days orders of six items or less all with embroidery are very common. We have rearranged our machinists as well as our actual machines in a way to ensure these orders can be quickly turned around as we put a greater emphasis on our product and our service ensuring we are the easiest company in the industry to order from.”

Targeting the B2C business through the use of this mass customisation service has enabled Glenmuir to reach markets where its B2B business would have taken longer to get to. Mikhel adds that through its e-commerce website Glenmuir now receives orders from as far as Chile and Australia. “Although we operate in around 30 countries with our B2B business, our e-commerce business continues to grow year on year and allows us to grow our global footprint very quickly,” he said.

Printwear & Promotion The Total Promotional Package

Printwear & Promotion The Total Promotional Package