In the fourth part of this series of articles about identifying and resolving transfer print problems, Sef’s area manager, Holger Beck, examines the problems associated with dye migration.

The digital transfer printing market has been growing for years, partly at the expense of the classic silkscreen printing, but it has also opened the way for new opportunities and markets. Access into the industry is easy, as you only need to make a small investment in plotters and transfer presses and you’re ready to go. But the possible problem areas also remain the same, new functional fabrics bring new problems with them.

I would like to devote this part to a subject which is often called resublimation. In my view this description is not correct. The term Sublimation is used to describe the process whereby a solid substance turns into a gas or vapour without passing through the intermediate stage of liquefaction. The term resublimation gives the impression that something has been sublimated again. However with the pigments used in fabric printing, Sublimation only occurs at temperatures over 190°C, but not at the usual transfer temperatures and certainly never at room temperature. When transfer films become discoloured on polyester fabrics it should be called dye migration. I would like to try to explain how dye migration occurs and what you can do to counter it and to what extent.

Four dye migration problems

Problems with dye migration can be divided into four categories, the simplest of these is: no polyester, no dye migration.

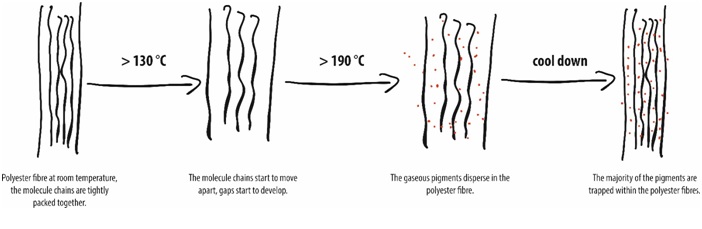

The second category is sublimation-coloured polyester. You can see that the fabric is coloured on the outside and white inside. Then it is coloured through sublimation for certain. This means that an intermediary carrier, usually paper, is printed with pigments which can be sublimated and at 190°C the pigments turn into a gaseous state, sublimate, disperse and dissolve into the polyester fibre.

The second category is sublimation-coloured polyester. You can see that the fabric is coloured on the outside and white inside. Then it is coloured through sublimation for certain. This means that an intermediary carrier, usually paper, is printed with pigments which can be sublimated and at 190°C the pigments turn into a gaseous state, sublimate, disperse and dissolve into the polyester fibre.

After cooling, the largest part of the pigments is trapped in the polyester fibre and can in fact no longer migrate, at least as long as it is kept below 130°C. Only a few pigments remain on the surface and you can usually ignore these. However if you now heat the fabric to over 130°C during the application of a transfer, then the polyester fibres will open up again and pigments can migrate to the surface of the fibre in solid form, without becoming gaseous. And they remain there even after the cooling process. These free pigments on the surface can now also migrate at room temperature. This leads to dye migration, the transfer becomes discoloured. Because the pigments for polyester which has been coloured through sublimation are very small, this happens very quickly, within hours or days, often you can see it straight after the pressing process.

This dye migration can be avoided for sublimation-coloured polyester, if transfer temperatures lower than 130°C are used (e.g. FlexCut X4). If you do this the polyester fibres remain tightly closed, you do not activate any additional pigments and the few pigments which are already on the outside of the fibre do not cause any damage.

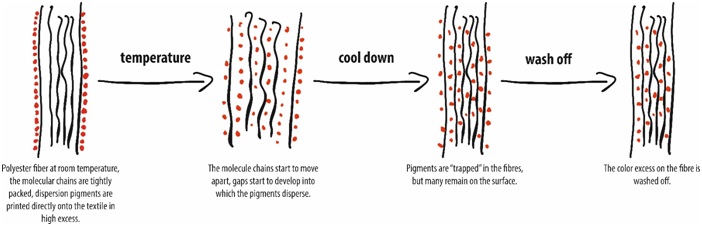

As well as the option of colouring polyester using sublimation there is also a second option – colouring through dispersion. Polyester which is coloured through dispersion is the third category of dye migration problems. You can see that the fabric is coloured on the outside and inside. When doing this, similar pigments are used to those used in sublimation, only here the pigments are larger and cannot sublimate. You therefore print the dyes directly onto the fabric, using excess dye. The following fixing process is similar to that for sublimation. The fibre opens due to the heat, the pigments disperse and dissolve into the fibre, the fibres close up again and the pigments are trapped.

But a lot of pigments remain on the outside of the fibre. These are usually washed off in a repeated industrial washing process with specially adapted detergents.

But a lot of pigments remain on the outside of the fibre. These are usually washed off in a repeated industrial washing process with specially adapted detergents.

To avoid dye migration, theoretically it is sufficient to keep transfer temperatures below 130°C. However if the fabric manufacturer has skimped on the washing process, then pigments remain on the surface of the polyester fibre which can migrated even if you keep the transfer temperature below 130°C. Dye migration will only become visible after a few weeks, as the dispersion pigments are really large and therefore need a longer time to migrate to the surface of the film. To avoid migration you definitely need a block film (e.g. FlexCut SBB Optima).

Unfortunately there is also a fourth category, softshell fabrics. These are also coloured using dispersion, but there are two other things to complicate matters. On the one hand they are made of microfibres whereby the surface of the fibres, onto which pigments could stick is increased.

On the other hand, they are not made solely out of polyester, but most also have a greater or smaller proportion of elastic fibres such as Lycra or Elastane. These fibres can also be coloured with dispersion pigments, but the pigments are certainly not trapped as with polyester at temperatures below 130°C. Here the pigments detach from the fibre composite even at lower temperatures and start to migrate. This explains the typical speckled damage which looks like mould which you get with softshell jackets. Sometimes the elastic fibres are on the top and the dye comes quicker, sometimes the polyester fibres are on the surface and it takes longer.

With softshell jackets the pigment excess on the fibre can be so great, that even “Subliblock film” no longer helps. The barrier layer in such films must be seen more as a sponge, which absorbs the excess pigments and does not let them reach the surface. If the sponge is full, because too many pigments are migrating, then it overflows. And the surface then also becomes discoloured.

What to do next?

What can the user do now? There is a really simple test which helps to assess how many pigments are on the outside of a fibre. That will help to answer the question as to which film should be used, low temperature films or migration block films or whether it would be best to do without the transfer entirely and embroidery would be better.

To do this, place a polyester strip which is half covered with paper carrier on the fabric to be tested, at 130°C for 30 seconds. At this temperature, as already stated, no new pigments are activated, but any pigments which are on the surface of the fibre will, for the most part, go into the polyester film. Using the colour difference between the covered and uncovered areas you can assess how many pigments there are on the surface of the fibre which are likely to migrate.

Even if, with the help of the test, you have now selected a block film, you still can’t be absolutely sure. The free dyes can migrate not only from the fabric through hot melt adhesive and coating, they can also migrate with folded fabrics directly onto the upper side of the transfer. Then even the best block film cannot help at all. This happens particularly if the fabrics are folded when they are still relatively warm or if they are stored folded for a long period of time. In order to avoid this, you should place separating paper between the transfer and fabric.

Another question which arises from time to time in connection with this is the question as to why you get pink patches when you use a white film on a black fabric… the film must be to blame. No, it is not. There are no pure black sublimation or dispersion pigments. In both cases, black is mixed from CMY and because the red/magenta pigments are smaller than the other colours, they come through first.

Sef film and vinyl products are available in the UK through Amaya Sales UK.

Summary

- A first indication of how whether migration is likely is down to the way the polyester has been coloured: If the fabric white inside, it is coloured through sublimation, if it is coloured inside, it is coloured through dispersion.

- It is preferable to use low temperature films such as FlexCut X4 on coloured polyester.

- To assess which film is to be used, test fabrics with a polyester strip on free pigments.

- With lots of free pigments, use separating paper when folding.

Printwear & Promotion The Total Promotional Package

Printwear & Promotion The Total Promotional Package