In the third part of this series of articles about identifying and resolving transfer print problems, Sef’s area manager, Holger Beck, this month deals with the influence of the surface of problematic fabrics on the adhesion of flock and flex.

Since we looked at the influence that the quality of the press, and the thickness of the fabrics and the protective films, have on adhesion or transfer parameters in the last part, I would now like to deal with the influence of the surface of problematic fabrics on the adhesion of flock and flex.

The composition of the weave/knit is always indicated for fabrics. You will be able to tell if a fabric is pure cotton, polyester, a mix of this or even nylon is concerned. If this was the only issue then you would have no problems, since even all flock and flex films adhere to pure nylon. Nylon if for all intents and purposes the trade name of DuPont for Polyamide 6.6, which alone is not a problem. The problem with nylon is that it is in most cases coated with a water and/or dirt repellent material. Substances are applied to the surface of the fibres which repel water and dirt, therefore making it hydrophobic. Hot-melt adhesive cannot stick to this water-resistant surface. Here you require a special nylon flex film such as for example FlexCut Maxx Nylon.

Flock and flex

FlexCut Maxx Nylon, in contrast to FlexCut Advance, has a copolyamide hot-melt adhesive rather than a polyurethane hot-melt adhesive. It is substantially more hydrophobic and can therefore also adhere to hydrophobic surfaces.

And why then is there not also a special nylon flock? For flock films, a further third variant of hot-melt adhesive is used – copolyester. This copolyester is less soft and less elastic than polyurethane and is therefore easier to cut. Additionally, copolyester has a substantially large adhesive spectrum and sticks to more surfaces than polyurethane – it therefore already covers a large majority of various protected fabrics.

Unfortunately manufacturers give no information on whether their fabrics are covered, or even with what their fabrics are covered with. There is a variety of different coverings including wax, acrylates, polyurethane, silicon or even fluorocarbon. Additionally, not only nylon fabrics are covered. There are more and more so-called functional fabrics coming onto the market, which provide firstly a covering or finishing of the fabric, and then influence the adhesion of the flock and flex. A specific statement of which film is to be used for which fabric can scarcely be found by us as manufacturers of transfer films.

Easy test

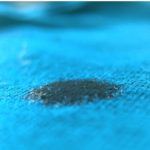

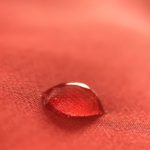

How can you deal with this? With an easy test you can at least roughly determine which surface is concerned, and therefore assess the type of film which should work on the fabric with this. Place the smallest drop of water possible on the fabric and assess the form of the drops.

The extent to which pre-pressing with washing with solvents or similar helps adhesion is often discussed in forums. This can all help but is not a must. The variety of possible coverings mentioned does not allow a clear opinion to be established. Nothing ventured, nothing gained or rather, annoy the fabric suppliers until they give a statement on the covering. This then makes it easier to assess what may help.

Luckily, another effect occurs rarely. It may occur that nylon flex or flock film appears as if it will hold after pressing. After two to three weeks it falls off again. The reason for this is recrystallisation. After cooling, the hot-melt adhesive is not immediately in its final form. The molecules lie almost flat next to each other, and the hot-melt adhesive is softer and stickier than in the final state.

The hot-melt adhesive sticks to very hydrophobic surfaces in this way. In time the molecules move around and get tangled. From this, the hot-melt adhesive gains its final properties, becoming less soft, less sticky and then it can no long adhere to the waterproof surface. As a result the film falls off. Polyurethane films recrystallise within around 24 hours, for copolyamide and copolyester it can take two to three weeks. Unfortunately, I do not know of any simple test methods for this, only waiting helps in this case.

In the next part of the series I would like to deal with resublimation, or properly expressed, with dye migration.

Sef film and vinyl products are available in the UK through Amaya Sales UK.

Printwear & Promotion The Total Promotional Package

Printwear & Promotion The Total Promotional Package